- Multan Rd, Sahiwal, Punjab

Menu

Sabri Dairy Engineering's milk homogenizers enhance product consistency by breaking down fat molecules, improving texture, stability, and shelf life while ensuring smooth, high-quality dairy products with advanced processing efficiency.

Our pasteurizers ensure safe dairy processing by eliminating harmful bacteria while retaining essential nutrients. Designed for efficiency and durability, they meet strict hygiene standards, guaranteeing superior product safety and quality.

Sabri Dairy’s butter forming machines deliver precise shaping, portioning, and consistency, optimizing production efficiency. Built with advanced technology, they enhance texture, quality, and reliability for large-scale and artisanal dairy operations.

Our high-performance milk separators efficiently remove cream and impurities, maximizing yield and ensuring top-quality dairy products. Designed for precision and reliability, they optimize processing while maintaining high industry standards.

Sabri Dairy’s butter churns efficiently produce smooth, high-quality butter by separating buttermilk with precision. Engineered for durability and performance, they maintain traditional taste with modern, high-efficiency processing.

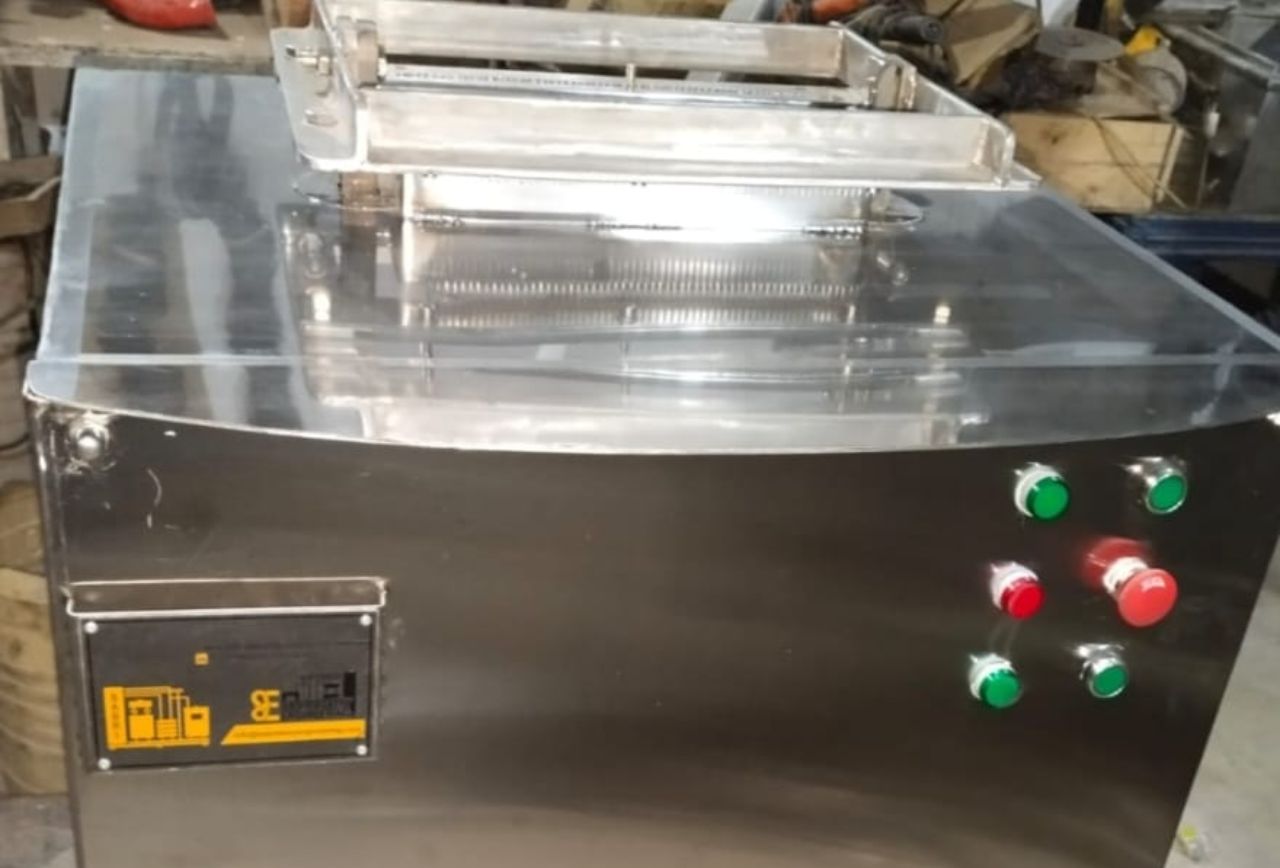

Our butter packing machines offer automated, hygienic, and efficient packaging solutions. They ensure accurate portioning, preserve freshness, and meet commercial and retail industry standards with precision-engineered technology.

Sabri Dairy's cheese slicers are designed to slice cheese into consistent, even pieces, ensuring precise cuts for packaging, retail, or further processing, maintaining product quality and reducing wastage.

Sabri Dairy's cheese millers efficiently process cheeses by grinding or milling them into smaller, uniform particles, enhancing texture and consistency for various cheese products, tailored to your production needs.

Sabri Dairy’s bottle fillers offer automatic, hygienic filling of dairy products like milk and yogurt, ensuring quick, precise, and contamination-free packaging for high-volume production lines with minimal product loss.

Sabri Dairy’s aging tanks provide optimal temperature and humidity control, ensuring consistent aging for cheese products, enhancing flavor profiles, and preserving texture during the maturation process for diverse cheese types.

Sabri Dairy’s plate heat exchangers offer highly efficient heat transfer for pasteurizing milk and other liquids, reducing energy costs while maintaining high product quality through effective temperature control.

Sabri Dairy’s mixing tanks are designed to efficiently blend dairy ingredients like milk, cream, and additives, ensuring even consistency and smooth texture for products such as yogurt, ice cream, and cheese.

At Sabri Dairy Engineering, we provide high-efficiency Yogurt Incubators designed to deliver consistent fermentation results for both small- and large-scale dairy operations. Our incubation systems maintain precise temperature

Our Cream Pasteurizer ensures safe, high-quality cream processing by eliminating harmful bacteria through precise heat treatment. Designed for energy efficiency and hygiene, it maintains natural flavor and texture.

Our Cheese Shredder delivers fast, uniform shredding for all cheese types, enhancing production efficiency and consistency. Built with durable stainless steel and safety features, it ensures hygienic operation, easy cleaning, and low maintenance.